Magnetorheological Fluid(MRF):

The Innovation of Smart Fluids

Magnetorheological Fluid (MRF) is an advanced smart material that revolutionizes the way we control vibration, shock, and motion.

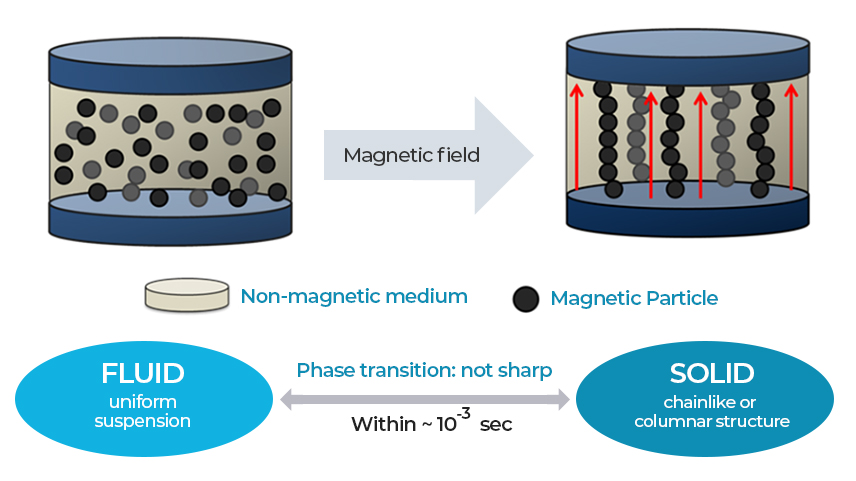

MRF is a special fluid whose viscosity (flow resistance) changes instantly when exposed to an external magnetic field. When a magnetic field is applied, the micro-sized or nano-scale magnetic particles inside the fluid align, transforming the fluid into a semi-solid state. And when the magnetic field is removed, the fluid returns to its liquid state. This transformation is completely reversible, allowing real-time control of mechanical properties such as stiffness and damping. Because of these unique properties, MRF can effectively control external shocks and vibrations in real time, and is widely used in various fields such as vehicle suspension systems, vibration control in building structures, and shock absorption in industrial machinery.

MRF operates inValve ModeandShear Mode, controlling the movement of the fluid depending on the strength of the magnetic field:

Valve Mode

When the fluid flows through a narrow passage (orifice), applying a magnetic field increases the flow resistance of the fluid, thereby adjusting the damping force.

Shear Mode

When the fluid experiences shear forces between two surfaces, applying a magnetic field increases its viscosity, resulting in higher shear resistance.

In conclusion, MRFs can precisely adjust viscosity based on the strength of the magnetic field, which provides MRFs with a smart technology that absorbs shock and vibration and effectively controls movement.

[Partner: Smarkotek]

Key Features of MRF

- 1. Instant Response Speed

- The viscosity changes within milliseconds when a magnetic field is applied, enabling real-time control.

- 2. Precise Control

- By adjusting the strength of the magnetic field, damping force and stiffness can be finely tuned.

- 3. Excellent Wear Resistance

- MRF is highly resistant to friction and wear, maintaining stable performance even with long-term use. This contributes to extending component lifespan and reducing maintenance costs.

- 4. High Yield Stress

- High yield stress allows effective resistance to external loads or shocks.

- 5. Wide Temperature Range

- Operates stably even in extreme temperature environments, making it suitable for various industrial settings.

- 6. Long-Term Stability

- Designed to prevent sedimentation, ensuring stable performance even after extended periods of non-use.